Lubrication-free linear and spherical bearings for baked goods gripper

Clean and even

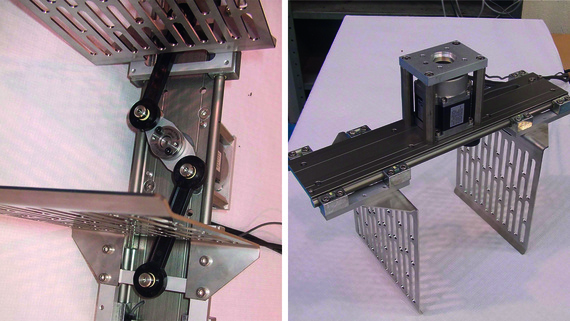

This gripper takes freshly baked products from a conveyor belt and stacks them in baskets. The gripping motion is achieved by drylin® W rails and drylin® W carriages. The slides are connected using igubal® double pivoting joints to ensure even movements of the two gripper arms. As always in the food industry, absolute lubricant freedom and cleanness have top priority for this application.Profile

- What was needed: drylin W linear guides, igubal spherical bearings

- Requirements: reliable as well as lubrication-free bearing components needed. Since baked goods must not be contaminated, the requirements for cleanliness and hygiene were very high.

- Industry: food industry

- Success for the customer: while the drylin bearings enable the linear movement of the gripper, the igubal components ensure the constant pivoting movement of the two gripper arms. The materials are completely lubrication and maintenance free.

Problem

The fully automatic packaging machine of the English machine manufacturer SP Technology Ltd. is used in the food industry, more precisely in the area of bakery products. A station includes a gripper, which is a handling system for the passing products. The function of the gripper is to place the incoming fresh bakery products in high quantity and under fast movement from a conveyor belt into baskets.Reliable and lubrication-free bearing components had to be found for the gripping movement and the linear motion. Since the baked goods must not be contaminated, the requirements for cleanliness and hygiene are very high, especially in the food industry.