Reliable, smooth-running energy chains and cables for the measuring system on the extruder

Pre-assembled readychain e-chains enable triple-digit savings

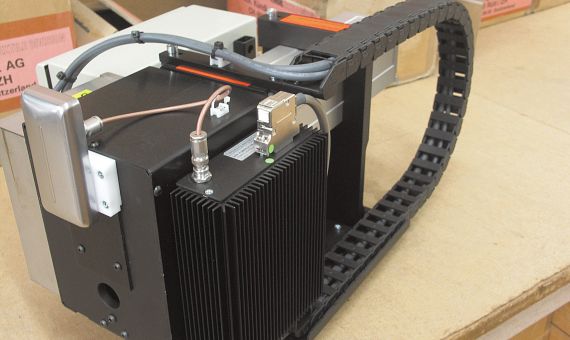

Pre-assembled readychain energy chains are used in this measuring and control system in blow-film extrusion. The system pays attention to the micrometre to ensure uniform width and thickness of the produced films, which can be used, for example, as packaging in the food industry. Before using the e-chains® of the E2/mini family, all necessary components for the energy supply system were harnessed by the company itself. The readychain solution helped save time, weight and costs.

Profile

- What was needed: E2-mini energy chains as pre-assembled readychain energy chain systems with chainflex control and data cables

- Requirements: The measuring device and energy chains must be in operation around the clock, 360 days a year. In addition there is heat, oily and dirty air. Since measurements take place in the μ range, the energy supply system should also be smooth-running.

- Industry: Plastics machinery, extruders

- Success for the customer: The readychain chains resulted in triple-digit savings. Reliable chainflex cables in the e-chains successfully replaced the previous cables, which quickly failed under the continuous tensile loads.

Problem

Whether packaging films for medicines or the food industry, whether insulating material for agriculture or construction, waste bags for the household or the office, transparent folders: the spectrum for films is huge.

And if an automated blow-film extrusion line is put into operation anywhere in the world, there is a good chance that it will be equipped with width and thickness gauges from Kündig. For more than 40 years, Kündig Control Systems has been developing ever new solutions for measuring films.

The devices display the measured data immediately and form the basis for ensuring the error-free blow-film extrusion. This increases film quality and reduces waste.

A wide range of versatile width and thickness measuring systems is available to users. Additional devices make the measured data visible or prepare it for further evaluations such as corrections to the manufacturing process.

The demands on the measuring system and energy supply system are therefore very high in blow-film extrusion. The entire process cannot simply be halted or shut down. As a rule, the devices are in use around the clock, 360 days a year. In addition there is heat, oily and dirty air. The energy supply system is only used for thickness measurement. With this capacitive system, measurements are made in the µ range.

Solution

Originally, every chain was harnessed by the company itself, but for many years now the specialist has been relying on our pre-assembled readychain energy supply systems. The chains are delivered directly with inserted cables, all plug-in connections, labelled and with defined projections according to customer specifications. This results in triple-digit savings for the customer.

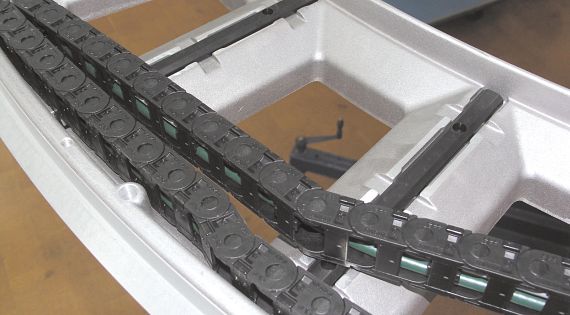

The chain itself is the energy chain system E2 mini. The compact chain can be easily opened, all the cables are inserted and not drawn in. This saves time and money. The chains are supplied in lengths of 5.25m for a side-mounted installation or used in the horizontal version with a length of 3.80m. The side-mounted e-chain is embedded in an aluminium slewing ring and rotates very slowly around the film. At 180°, the energy chain reaches the turning point.

A data cable and a control cable from our chainflex cable product range for use in energy chains round off the overall solution. Despite the slow movement, the cables are stressed by the constant changes in length resulting from the s-shaped movement and the resulting permanently changing tensile loads. The originally inserted cables from another manufacturer, had here permanently the problem with corkscrews and failed. Since the cables for energy chains were also purchased from us, there have been no more problems, according to the manufacturer.

Peter Bünter, Head of Purchasing and Production at Kündig Control Systems

Here you can find the products used

Energy chains E2-mini

- Easy assembly and disassembly

- Compact, space-saving design

- With particularly quiet operation

Pre-assembled e-chain

- Up to 95% reduction in harnessing time

- Less downtime and costs

Control cables

- From 12 cores with cores wound in bundles with short pitch length

- Long service life in energy chains

Data cables

- Versions with different electrical constructions

- Long service life in energy chains