Robust 3D energy chains for industrial robots in injection-moulding systems

Automation in injection moulding: new energy chain avoids failures and protects cables

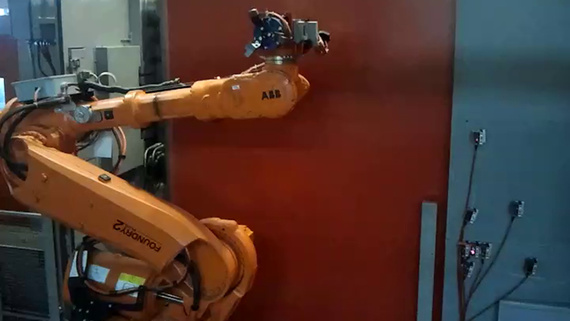

At Movi.Tec Srl Unipersonale in Italy, a triflex energy chain protects the pneumatic cables that are attached to a robot: it is an integral part of an injection-moulding system. The universal module TRC.RS.40.R is now installed to protect the e-chain from the generated heat and to prevent the system from failing - it provides absolute safety and reduces vibrations while the robot goes through its workflow.Profile

- What was needed: triflex energy chain as a universal module including retraction module

- Requirements: the cable guidance has to be strong, but still guide all pneumatic cables in a gentle and flexible way. It is designed to prevent the cable package from sagging so that the working area is not obstructed.

- Industry: injection moulding, automation

- Success for the customer: safety during operation, avoidance of damage to the cable guidance and cables, reduction of vibrations

Movi.Tec Srl Unipersonale, Massimo Musicò, Nichelino, Italy

Problem

What do you do if your industrial robot's cable guidance constantly hangs around in the working area, preventing the system from moving freely and even causing damage to guidance and cables? This problem affects many industries related to the automation of machines or entire factories. The reason is that robot arms perform complex movements on several axes, in which the robot is either contracted or expanded. The cable guidance, which is supposed to simulate these movements, is sometimes strained or sags when the robot arm contracts.This problem also concerned the Italian company Movi.Tec srl, but in an even more challenging way: the industrial robot, which is supposed to remove sprue in injection moulding, is surrounded by extremely high temperatures. The cable guidance used by the customer was sagging, came into contact with hot surfaces and literally melted away - along with all cables within.

Solution

As an integral part of the injection-moulding system, a new, better form of cable guidance had to be found. The aim: a cable hose that was tight-fitting even when the robot arm is contracted, but which releases enough cable length when the robot extends. What sounds impossible at first is realised using so-called retraction modules. The idea behind it: the retraction module, which is also installed on the robot arm, releases exactly as much hose as is needed. The manufacturer therefore opted for a TRC.RS.40.R universal module. This combines a triflex 3D cable guidance system with a retraction module. The triflex cable guidance system enables high flexibility even in the sixth axis and allows torsion of +/-10° per chain link. The energy supply system allows a high tensile force absorption of up to 100N, is dirt-repellent, robust and resistant to impacts, abrasion and swarf. It was developed as a universal solution for complex movements on industrial robots across all industries and applications.Customers can also benefit from this today. From now on, failures due to damaged cables are prevented in injection moulding. The triflex provides absolute safety and reduces vibrations while the robot runs through its workflow.