Cambiar idioma :

¿Hasta qué punto son sostenibles los motion plastics?

El plástico es un material muy discutido. Sabemos que los plásticos de alto rendimiento de igus pueden contribuir a proteger los recursos y el medio ambiente y hemos hecho de este aspecto el centro de nuestras actividades empresariales. Nuestro objetivo declarado es ser neutros en CO₂ en el uso de nuestros edificios y producción para 2025.

Para lograr este objetivo, estamos aplicando diversas medidas, algunas de las cuales le presentamos en esta página y en el folleto "Nuestro camino hacia la sostenibilidad". Consideramos los plásticos de nuestros productos en tres fases:

Más sobre la sostenibilidad en igus®

Antes: Producción de plásticos

Certificaciones medioambientales y climáticas

Nos esforzamos por conseguir mejoras continuas en nuestra gestión medioambiental y energética. Para ello, nos comprometemos con una estrategia corporativa sostenible en lo que respecta a los aspectos ecológicos, económicos y sociales. Los hemos resumido en nuestra política energética y medioambiental.

Cuando se utilizan plásticos

Sin lubricación

Cada año, 27 millones de toneladas de grasa lubricante contaminan el medio ambiente en todo el mundo. Nuestros plásticos no necesitan lubricación.

Después: Plásticos tras su uso

Novedades sostenibles

Plantación de árboles

Nuestras actividades de plantación de árboles comenzaron en 2019 como regalos de Navidad para los clientes y desde entonces se han convertido en un gran número de proyectos de reforestación.Hasta la fecha, hemos plantado un total de76 280 árboles, no solo en Alemania, sino en todo el mundo. Desde árboles jóvenes hasta grandes árboles urbanos, plantamos y cuidamos árboles y arbustos en campañas pequeñas y grandes. Al crear nuevas zonas arboladas, queremos contribuir a reducir las emisiones de CO

Proyectos e iniciativas de conservación de recursos

Asociación con la Declaración del Clima de Colonia

En diciembre de 2024, igus se unió a la Declaración del Clima de Colonia y, junto con los demás socios, tiene como objetivo lograr la neutralidad climática de la ciudad de Colonia para 2035. Con este paso, reafirmamos nuestro compromiso con las prácticas empresariales sostenibles y el apoyo a las medidas de protección del clima urbano. Felix Hülder, Lean Engineer Green Production de igus, sobre la nueva asociación: "Como empresa, estamos trabajando actualmente en el desarrollo de un plan holístico tanto para la sede de Colonia como para todo el mundo, que incluye un plan de acción que incluye una estrategia global para llegar a ser climáticamente neutros."

Sostenibilidad para nuestros cables chainflex

La sostenibilidad es uno de los mayores retos de nuestro tiempo, especialmente en la industria. Queremos abordar esta cuestión con nuestros cables chainflex. ¿Qué estamos haciendo ya para que chainflex sea más sostenible? ¿Cómo podemos mantener nuestros altos niveles de calidad y reducir al mismo tiempo nuestra huella ecológica? ¿Y puede el cliente beneficiarse también de ello?

Movilidad sostenible con la igus:bike fabricada con plástico reciclado

Con nuestra igus:bike y la plataforma igus:bike, queremos promover la movilidad sostenible y urbana. La bicicleta está fabricada casi en su totalidad con plástico, en su mayor parte procedente de residuos plásticos reciclados. Es robusta, requiere poco mantenimiento, no se oxida y no necesita lubricación adicional. Utilizamos la plataforma para mostrar el estado actual de la técnica y ayudar a los fabricantes de bicicletas y componentes a crear redes e intercambiar ideas entre sí.

Envíos climáticamente neutros con UPS

A partir del 1 de enero de 2024, en igus Alemania hemos hecho nuestros envíos más sostenibles y hemos introducido una nueva opción de envío: "UPS Carbon Neutral Shipping". Desde entonces, realizamos envíos climáticamente neutros con UPS y las emisiones de CO2 generadas al enviar nuestros productos se compensan. Esto se hace a través de proyectos globales reconocidos para reducir los gases de efecto invernadero, por ejemplo, mediante la protección de la selva tropical en Brasil, el tratamiento de aguas residuales en Tailandia o la recuperación de metano en los Países Bajos.

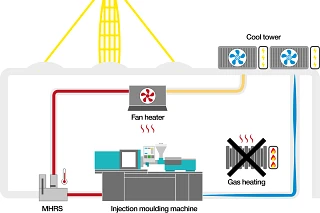

Nuestro concepto de calefacción con calor residual de la producción

Calentar con gas, ¿es necesario? En el proceso de producción se genera mucho calor, seguro que podemos hacer algo con él. ¿Cómo podemos aprovechar el calor residual? Un equipo de ingenieros de igus se hizo esta pregunta y empezó a probarlo. El resultado: el concepto de un sistema de calefacción que aprovecha el calor residual de las máquinas. El plan era dejar de calentar los edificios de la planta de Colonia con gas y poner el concepto a disposición de ingenieros e ingenieros mecánicos, en otras palabras: de la industria. Lo llamamos MHRS: Sistema de Recuperación del Calor de las Máquinas.

Residuos atrapados en el dispositivo (izquierda); río después de la recogida (derecha).

Plastic Fischer - contra los residuos plásticos en los ríos

Entre 8 y 12 millones de toneladas de plástico acaban cada año en los océanos, la mayoría a través de los ríos. Plastic Fischer empieza aquí mismo y recoge los residuos en los ríos, lo que resulta más rentable que pescar en el mar. ¿Cómo funciona el proyecto? Las personas que trabajan en el lugar pescan la basura de los ríos con equipos y reciben a cambio unos ingresos regulares. Los residuos plásticos recogidos, que suelen clasificarse como no reciclables, se envían a plantas de reciclado térmico, donde se incineran con recuperación de energía. igus financia la recogida de un total de 10.000 kg de residuos plásticos. Esto ha proporcionado a al menos 34 personas de Kanpur y Mangalore (India) unos ingresos regulares durante el tiempo que dura la recogida, a los que se unen ayudantes algunos días.

Pulpo del Rin - igus apoya la trampa flotante de residuos

Cada día, una tonelada de residuos flota por el Rin hasta el Mar del Norte. Una cantidad inmensa. La asociación K.R.A.K.E., con sede en Colonia, lleva años organizando campañas de recogida de residuos en el Rin y sus alrededores. En septiembre de 2022 dieron un gran paso adelante con la trampa flotante de basura. La construcción, inspirada en el modelo londinense, es una trampa pasiva hacia la que deriva la basura flotante. Los miembros del club vacían regularmente el pulpo de basura y la basura se recoge en tierra. En colaboración con la Universidad de Bonn, estos residuos se analizan científicamente para realizar un estudio a largo plazo sobre los residuos plásticos en el Rin.

Clean igus - nuestra iniciativa para evitar los residuos plásticos

En el pasado, ocurría a menudo que las piezas nuevas de nuestras máquinas de moldeo por inyección no acababan en los contenedores de recogida, sino en el suelo, y por tanto en los residuos. La cantidad de residuos se acumulaba debido al gran número de producciones y a la gran cantidad de máquinas. Optimizando las máquinas y la cinta transportadora de varias maneras, pudimos reducir la tasa de residuos en un 21% en 2021 (residuos de producción + material procesado). Los huecos en las transiciones se cerraron con láminas magnéticas, las máquinas y las cajas de recogida se equiparon con láminas metálicas y cubiertas o tapas, las cintas transportadoras se centraron y fijaron en su sitio, los cepillos y las placas guía dirigen las piezas por el camino correcto, las marcas en el suelo y las cuñas de tope garantizan la colocación correcta.

Utilizar la energía en tierra para combatir las emisiones contaminantes en los puertos de contenedores

El funcionamiento de los generadores diésel de los portacontenedores en los puertos es un grave problema. Polvo fino, óxidos de nitrógeno y azufre, así como emisiones de CO2 se liberan al medio ambiente y a la atmósfera por toneladas. Con la toma de corriente móvil iMSPO creamos en 2022 la posibilidad de que los buques portacontenedores puedan abastecerse de energía en tierra de forma sencilla, rápida y, sobre todo, flexible. Si además esto es ecológico "" , el camino hacia el puerto de cero emisiones "" está despejado.

Medidas de ahorro de recursos en todo el mundo

Actualización del camino hacia la neutralidad climática

En 2023, causamos un 89% menos de emisiones de CO****2 que en 2020 (excluida la flota de vehículos). Esta cifra se refiere a las emisiones de Alcance 1 y Alcance 2. El cambio a la electricidad verde y al gas neutro para el clima en 2021 desempeñó un papel importante en este sentido. Para 2025 están previstas o ya se están aplicando otras medidas, que le presentaremos en detalle tras hacer clic en el siguiente enlace.