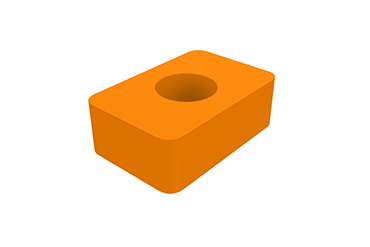

Customised, mechanically manufactured sliding blocks for lifting platform

Profile

- What was needed: Sliding blocks in the linear unit of the 2-column lifting platform

- Industry: Material handling/lifting platforms

- Requirements: High surface pressure, good friction and wear properties, the workpiece must be able to absorb axial and radial forces

- Manufacturing process and material: Extruded iglidur RN44 plate material, mechanically processed

- Advantages for the customer: Maintenance-free, low costs and direct purchase of the finished component

We were able to help our customer, a well-known manufacturer of products for vehicle testing and workshop equipment, with our RN44 material for the new design of a 2-column lifting platform for motor vehicles. The customer needed a sliding block to guide the linear units in the columns. The task of this component is to absorb radial and axial forces, depending on the load position. The aim was to find a material with good friction and wear values. We were not only able to provide the customer with our bar stock, but also deliver the mechanically finished component. This was manufactured from an iglidur bar stock plate using a CNC milling machine.