Vibration-damping plain bearings for microlight aircraft controls

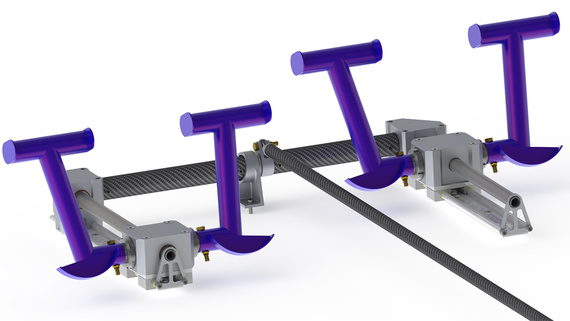

For high forces, drylin linear bearings are used in this aircraft steering system.

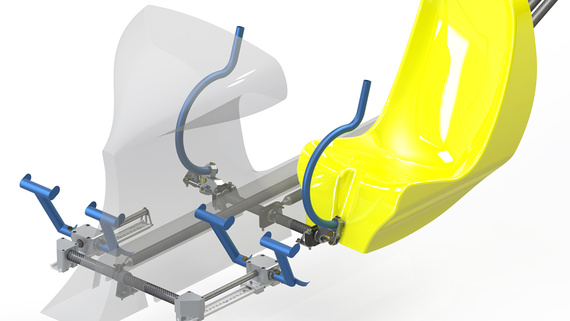

These pedals for control of ultralight aircraft can be moved easily, smoothly and synchronously. In the cockpit of the light plane, there are usually two pairs of pedals arranged in parallel. This allows both pilots to control the rudder and thus to provide an optimal flight position. To avoid sudden unwanted movements, the pedals must respond very precisely and smoothly. This is achieved with a drylin® linear guide. The guides are also lubricant-free and therefore maintenance-free.Profile

- What was needed: drylin linear plain bearing

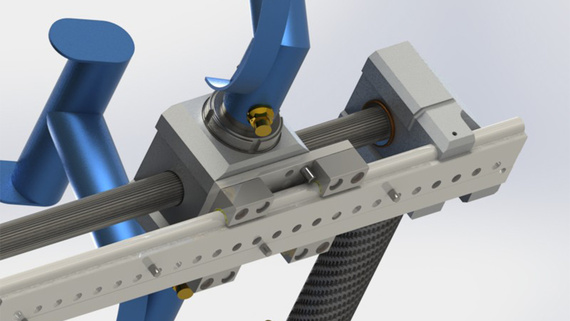

- Requirements: The steering must always react very precisely and smoothly. In addition, the pedals must move easily, smoothly and synchronised. As high axial and radial forces act on the steering system, the bearings must also be able to withstand high forces.

- Industry: aerospace, aviation industry

- Success for the customer: The customer decided in favour of the drylin bearings for several reasons: They are vibration-damping as well as lubricant and maintenance-free. The material properties allow high force absorption, while at the same time saving the customer money both in terms of purchase and running costs.

Problem

The project deals with the development of the control system for a microlight aircraft. The two pilot positions arranged in parallel each have a pedal (to control the rudder) and a control bar (to control the ailerons and the balancer) with synchronised movements. A torque tube, which leads to the transmission chain and to the pilots' levers at the centre and at the ends of the links, is affected by both radial and axial loads. During flight operation, there must be no jerky and unwanted flight movements, meaning that the pedals must always react very precisely and smoothly. In addition, they must move easily, smoothly and in a synchronised manner.Solution

In view of the estimated considerable axial load, metal reinforcements were designed to span the connection and rest on the screw. The bearings are also subjected to high loads. The decision was made in favour of drylin linear bearings for various reasons. This means that they still have an affordable purchase price despite their high performance and flexibility. They are easy and economical to maintain. If necessary, it would also be very economical in terms of spare parts costs. The plastic support can isolate some of the vibration unavoidably generated by the aircraft and thus dampens vibration. No lubricants are required for sliding, so no binding agents need to be provided. This also means that cleaning is much easier due to the lack of greasy lubricants.Bercella srl, Riccardo Bertini, Varano Melegari, Italy