Robust, wear-optimised guide systems in EME Parker linear actuators

Durable, lubrication-free complete linear bearings and linear actuators with toothed belt drive

Conventional skate wheel guides in particular often have both mechanical and economic disadvantages in linear actuators. For example, their stiffness is very poor. They are susceptible to high moment loads and allow only limited acceleration. In addition, there is usually time-consuming and cost-intensive maintenance work. Guide systems with plastic elements put an end to these problems and open up many more advantages for the user.Profile

- What was needed: Linear bearing systems from igus

- Requirements: Linear actuators in conventional systems often have problems such as carrying dead mass with the slider, an unfavourable lever ratio between support and load arm, they require lubrication and cleaning as well as regular maintenance

- Industry: Manufacture of machine parts

- Success for the customer: igus guide systems are the ideal alternative for Parker EME: e.g. they are extremely robust, have optimum coefficients of wear and friction, and require no lubrication

Discover all products for machine tools

Products used

Problem

Linear actuators with conventional guide systems can cause a variety of problems in a design, for example they often introduce a large moving dead mass at the slider. In addition, there is an unfavourable lever ratio between the support arm and the load arm in the case of internal guides, as it is located far away from the load. The speed is limited (especially with recirculating roller guides) and the acceleration is restricted. Skate wheel guides in particular give way quickly under high moment loads - they are very susceptible because roller axes can be bent or misaligned. Not to mention the lubrication that is usually necessary with these machine elements, which attracts dirt and where discharged grease or oil can contaminate the overall system. They must be installed in a protected manner or provided with a bellows as a cover. The regular maintenance required - mostly cleaning and relubrication - makes them additionally expensive. Last but not least, the multi-part overall system means high assembly costs. Christoph Lindemann, product manager for mechanical components and systems at Parker EME in Offenburg, is also aware of the risks and side effects in practice: "Our linear actuators to date are mainly equipped with skate wheel guides. For clearance-free adjustment, the skate wheels are attached to the slider with screws and eccentric bushes - a so-called "cantilevered attachment" is created. If the skate wheels are already working close to their maximum load capacity during normal operation, a collision, for example, can easily lead to the misalignment or even bending of these fastenings. Guides that are overloaded even for a short time can thus cause severe permanent damage to the entire system. The ratio of harmful to typical exposure is in the range of 3:1 and 5:1."Solution

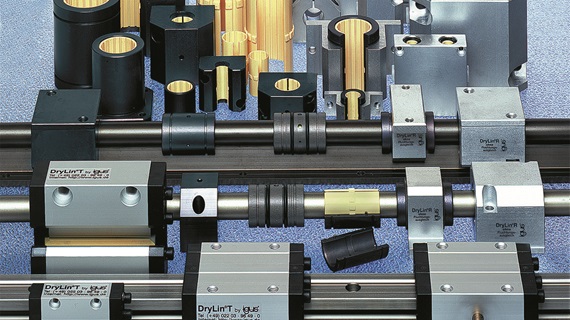

The drylin WQ guide systems from igus, which Parker EME installs in its linear actuator "LCB", are different. Here, this ratio ranges between about 100:1 and 500:1. These figures show the extreme robustness of the guides. After all, the glider transmits the forces directly to the guideways. There is no possibility of adjustment; the danger of bending is practically excluded.The sliding elements are made of high-performance polymers. For most applications, the use of the material iglidiur J is recommended due to its wear and friction properties. Basically, the drylin linear bearing systems are designed for dry operation. Contamination by grease or oil is now a thing of the past. Ambient dust or abrasion during machining are not bound to the bearing position. drylin guides are divided into two main groups with different geometries: profile rail and shaft guides.

In the drylin T system, the carriages run on a T-rail made of hard-anodised aluminium. All connection dimensions are the same dimensions as most commercially available recirculating ball guide systems. A miniature version can be accommodated even in the smallest installation spaces. Extremely flat "N" variants are available in four sizes from 17 to 80 mm rail width. The slides are movable in C-profiles made of anodised aluminium.

drylin R linear plain bearings, on the other hand, which correspond to the size of ball bushings, use round shafts as counter partners. Thereby different shaft materials are used. Thus, hard-coated aluminium shafts guarantee low wear and low coefficient of friction. The drylin W linear guides used by Parker EME combine two round shafts, rectangular guides and the support profile for the linear actuator in one profile made of hard-anodised aluminium. They allow the greatest freedom of design through various shaft diameters, profile widths, carriage lengths and geometries.

For cost-conscious design

All igus guides are particularly characterised by simple design, robustness and compact construction, design focus for the entire "LCB". This results in a low moving dead mass due to the glide pads and the slim runner plate as well as a wide guide base in close proximity to the load. Speeds can reach up to 8 m/s; unrestricted acceleration is possible. Last but not least, the actuator has a high level of resistance to chemicals and corrosion. Perhaps the most important plus point of guide systems, however, is their cost-effectiveness.On the one hand, this is due to the favourable purchase price, and on the other hand to the minimal operating costs, as drylin works maintenance-free even in harsh environments. Since there is no need for lubrication, the guide does not attract dirt and does not contaminate the overall system by leaking grease or oil. Expensive machine downtimes are a thing of the past. Additional protection or scrapers are also unnecessary, which reduces the number of components to be mounted and further lowers costs. Lindemann: "For our skate wheel guides, at least twelve skate wheels have to be pre-assembled, mounted and adjusted, whereas for the guide system, only four sliders. The working time alone for assembling the guide system is reduced to an estimated 10 per cent." When the wear limit is reached, the user can simply change the glide pads himself within a few minutes. Even pneumatic and servo-pneumatic solutions can be advantageously replaced, according to Lindemann, whereby the better positionability at any point is also decisive here: "Actuators with linear guide systems can even make some designs with linear motors look pale, if it is not so much a matter of accuracy, but rather the lower energy consumption for oscillating movements that is important. This is due to the much lower movable dead masses."