Module Connect ensures fast

commissioning of the energy supply system in the wood industry

Profile

- What was needed: ready-to-install harnessed energy chains that can be put into operation quickly

- Requirements: easy installation, great time savings, one central interface instead of many individual connectors

- Product: igus readychain® harnessed energy chain & igus Module Connect interface solution

- Industry: wood industry

- Success for the customer: simple as well as quick commissioning and the customer is able to disconnect and connect the self-coded assembly at any time if service is required.

About the application: it involves four machines used in the wood industry to make furniture. They function similarly to a warehouse with ready-made wooden elements.

Inside the machines there are special partition walls behind which the wooden elements wait for their next processing step. They work with very high precision and are in operation 24 hours a day.

In addition, the machines each have two axes, motors, many sensors and other signals, which is the reason why a central and compact interface offers a great advantage.

The challenge

The challenge for our customer in this project in particular was that the path of the cables through the machine from the consumer unit to the switch cabinet is 100 metres. This creates logistical challenges in the event of service, where there is planned or unplanned downtime. On the one hand, a fully harnessed energy chain with 100 metres of cables including intermediate plug-in points could be ordered and this correspondingly heavy system is then routed through the hall, which takes a lot of time and effort for installation. Or, it is possible to obtain individual parts which are lighter and easier to handle, but which in turn lead to additional work during installation and completion and are prone to errors. In addition, there is a loss of production during the installation period.

In addition, the customer's four machines operate independently of each other. However, they are connected to each other via a safety circuit. If one machine fails, all four machines are stopped. For this reason, it is so important for our customer to be able to replace the entire energy chain safely in the event of a machine breakdown, saving valuable time.

Solution

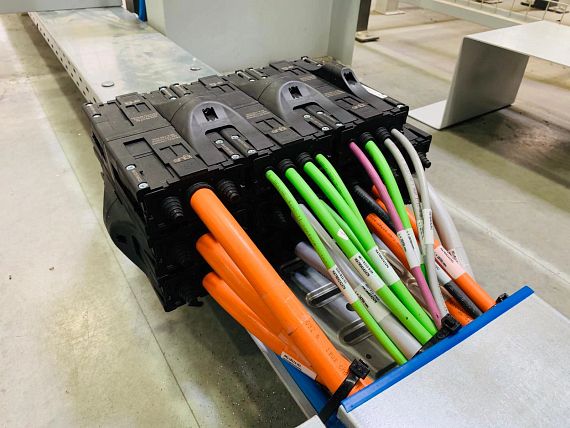

The ready-to-connect readychain complete solution offers the customer the greatest advantages in this application. We have a fully harnessed energy chain, including the plug and play interface solution Module Connect for their machines. The cable set was completely implemented with igus' own chainflex cables, which are specially designed for moving applications. Furthermore, the interface solution with Module Connect was planned in such a way that the different types of cables, from servo and bus cables up to data cables, could all be safely connected to the system together in one interface. This could only be implemented in a compact and safe manner thanks to the modular structure of Module Connect with its numerous application possibilities.

Thanks to the igus interface solution, the customer is now able to unplug and plug in the self-coded assembly - absolutely securely and without specialist personnel. The individually configured assemblies now offer a high degree of modularity as well as safe production processes. Often the work on this system takes several days. With Module Connect, not only has handling been simplified considerably, but downtime and maintenance costs have also been significantly reduced.

Find out more about Module Connect

motion - magazine for energy chain systems®

Improve the performance of your machine ... Cost down.

In this igus® magazine you will find numerous possibilities and application examples of how you can bring your tech up and/or cost down with ready-to-install energy chain systems.Order your personal copy here