Plain bearings allow clearance-free installation of the locking hook in the vehicle

iglidur plain bearings in locking system for vehicles enable higher process reliability

As part of a project, the task was to design and implement a locking system in the rear area of a vehicle, consisting of six identical locking units. HS GENION GmbH sometimes relies on iglidur bearings here, which enable the clearance-free assembly of the locking hook. Unlike previously used metal-plastic bearings, the iglidur solutions enable the use of fewer parts and a higher process reliability during assembly.Profile

- What was needed: iglidur plain bearings

- Requirements: The list of requirements specifies among other things maintenance-free bearings with a long service life that must be able to withstand high static and dynamic loads and offer both lightness and ease of mounting. A cost-effective solution was also sought

- Industry: Automotive industry

- Success for the customer: iglidur bearing enables clearance-free installation of the locking hook; Unlike previously used metal-plastic bearings, the iglidur solutions allow the use of fewer parts and a higher process reliability during assembly

Problem

HS GENION GmbH offers its technological and development expertise in the field of automotive engineering as a strategic partner for all development services up to the start of production for the complete vehicle. In the process, ever higher demands are being placed on quality, safety, reliability, service life and costs while reducing the development time of the vehicles. These requirements affect all systems, assemblies and individual parts down to the smallest details.It also applied to the design and implementation of a locking system in the rear of a vehicle, consisting of six identical locking units. The task was to develop a locking unit that had to meet a number of requirements. It should be maintenance-free, have a long service life, withstand high static stress (at operating temperatures between - 15°C and + 80°C) and high dynamic stress with vibrations, and minimise the risk of wear. In addition, lightness, low noise when working, no clearance, corrosion resistance, easy assembly and disassembly, the number of individual parts (as low as possible) and a limitation of costs also played a major role.

Solution

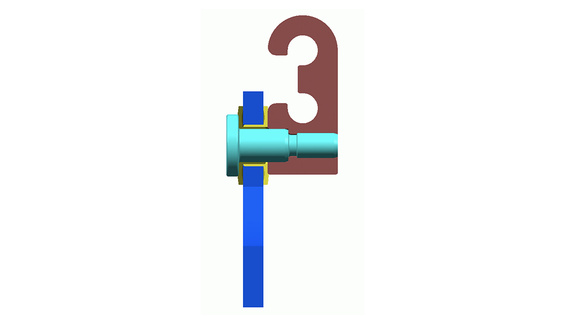

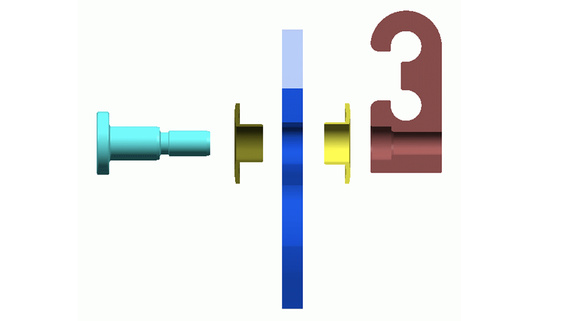

Our guide rails, among other things, were used in the project planning of the pre-series prototypes. Specifically, the implemented locking unit consists of a guide rail and drive mechanism (part of a pre-assembled module), locking hooks (locking hooks and igus bearing pairing supplied pre-assembled) and a screw shaft.The advantage of the simple solution is above all the short installation time, which is limited to a simple screw connection. A decisive role in meeting all requirements was the application of an iglidur plastic bearing pairing with a spring-loaded flange, which enables the clearance-free installation of the locking hook. The overlapping of the two bearings was necessary to avoid the possibility of losing them (due to very short insertion length) during transport and handling. In the previous prototypes, metal-plastic bearings and corrugated washers were used. The corrugated washers proved to be a danger to the process reliability of the assembly (small loose parts). An important contribution to reducing the number of parts and simplifying assembly has been made by the screws, which, thanks to their self-locking property, enable the elimination of additional fasteners and securing devices.

Alexander Kantor, HS Genion GmbH