Turn, tilt, fold, slide - maintenance free and comfortable

Among architects Schlechtendahl & Söhne GmbH & Co. KG is known among architects and planners of public and commercial buildings for their development and manufacture of high-quality fittings for windows, doors and facade elements. For this purpose, maintenance-free sliding and bearing elements from the igus® construction kit are used and are exposed to high degrees of stress – due to high contact pressure, diverse environmental influences and the requirement of being able to withstand a million manual operations.

In the "key region" of Heiligenhaus there is a unique concentration of companies in lock and hardware technology - and it even has its own college campus focused on mechatronics. Some of the manufacturers in the region supply the global automotive industry with car locks, others are working in building services engineering. This includes WSS Wilh. Schlechtendahl & Söhne GmbH & Co. KG.

In the "key region" of Heiligenhaus there is a unique concentration of companies in lock and hardware technology - and it even has its own college campus focused on mechatronics. Some of the manufacturers in the region supply the global automotive industry with car locks, others are working in building services engineering. This includes WSS Wilh. Schlechtendahl & Söhne GmbH & Co. KG.

In the premium quality and innovation segment

Established in 1906 and employing about 350 employees in Heiligenhaus, the company first specialised in fittings for windows, doors and gates but, for around 20 years, has been a supplier of facade components – and, with its wide range of products, is clearly in the premium segment in terms of quality and innovation.Dipl.-Betriebswirt Robin Fasel, CEO of WSS: "We develop and supply components with which elements of the building shell can be opened. " Many well-known and architecturally sophisticated buildings have fitting systems from WSS – for example, the headquarters of Daimler and Sony in Berlin, the GAP 15 office building in Düsseldorf or the eye-catching "Colorium" in the media harbour there and the Telekom office tower in Bonn.

For these and many other buildings WSS has developed customised fittings for lowering, folding, turning, exhibiting and moving façade elements. No less challenging is the catalogue range of the company, which in addition to various window fittings includes, among others, panic locks with electronic handle control and roller bands of heavy fire protection and emergency exit doors.

Trends: More visibility, more weight, more comfort

Thereby, a significant trend is visible in the true sense of the word. Robin Fasel: "The window and door surfaces are becoming ever larger, so that the rooms are flooded with light. This means that they are also becoming heavier, especially in view of the fact that multiple glazing is now a standard feature of new buildings for energy reasons. At the same time, however, users expect greater ease of use: during opening and closing, the weight should not be noticeable. “Under these framework conditions, the design and development team led by Giovanni Zaccaria has developed fittings systems, whose features reveal themselves only if you look very closely or retrace the complex movements, and also when you consider the forces acting on the individual components.

High requirements on plain bearings

As an example, take a bearing that is attached to the hinge of a door or window fitting. Giovanni Zaccaria: "The entire weight of up to 250kg acts on the flange of the lower bearing - on a few square millimetres. Moreover, tipping loads occur when a window is open. " Nevertheless, the bearing must be able to move easily and without sticking Above all, it must not wear out: customers and users basically expect fittings to operate for decades without any maintenance - even though they are moving components.Plain bearings from the igus® construction kit are proving their worth under these conditions. Depending on the application, WSS design engineers use bearings made of iglidur® J or iglidur® G. These two materials are high-performance polymers with a lubricant component that is permanently incorporated in the material and therefore ensures good sliding properties for the entire service life of the bearings – without any additional lubrication.

Adverse environmental conditions

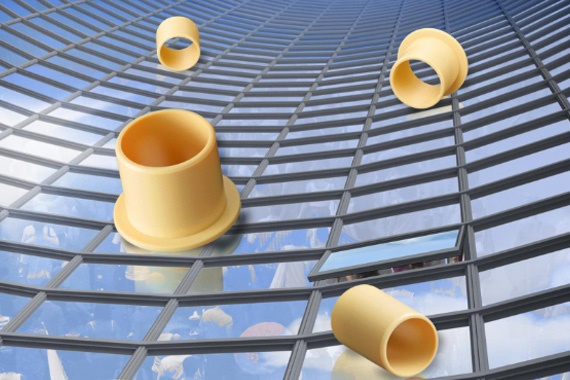

The iglidur® components most frequently used by WSS are guide bushes and collar bushes. The bearings typically have an inner diameter of six to twelve millimetres. They have to work flawlessly after years of UV exposure, without becoming brittle. The components designed by WSS and therefore the igus® bearings must be impervious to humidity, low temperatures down to -30°C, high temperatures up to 80°C and aggressive sea air.These requirements apply to special designs of facade fittings as well as to the WSS catalogue products, for example, clamp hinges, butt hinges of heavy emergency-exit and fire doors as well as high-quality and robust glass fittings that are made in large quantities and are also fitted with igus® bearings.

One million cycles without measurable wear

At "Bau 2015", WSS presented a new system of fittings for parallel opening windows, whereby the iglidur® bearings support linear and not rotary movement.* (*Note: The article will appear only after the exhibition, and hence in the past tense.) The fittings - including the bearing - were subjected to a comprehensive series of tests. The design department, where 35 technicians and engineers are employed, houses a test laboratory, where new products are in motion for up to six months and exposed to different environmental conditions. The igus® bearings always perform as expected. Giovanni Zaccaria: "When we finish the tests after one million cycles, we still haven't found any wear on the bushings - despite the high compressive stress and edge load."The iglidur® components therefore comply with the high requirements of WSS regarding quality, durability and freedom from maintenance. The architects and builders also expect these properties from the WSS fittings, and their expectations are often not only met but clearly surpassed. The igus® bearings make a contribution to this.