Bearing in prosthesis: smooth-running, quiet

Durable, low-noise and maintenance-free iglidur bearings replace metal bearings in knee prosthesis

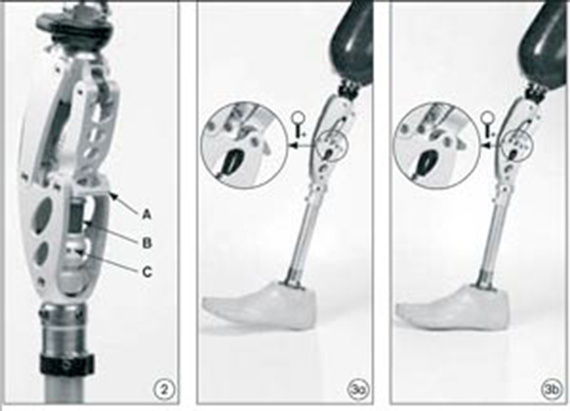

New bearings had to be found for the knee joint prosthesis "3R60 EBS" from the globally successful orthopaedic specialist Otto Bock Health Care GmbH. The previous needle and bronze bearings were susceptible to dust, developed noise and clearance and formed fretting corrosion. With plastic plain bearings made of iglidur Q and iglidur W300, these problems were now avoided. They are also particularly light, smooth-operating and cost-effective.Profile

- What was needed: Plain bearings made of iglidur W300 and iglidur Q

- Requirements: Previous metal bearings were susceptible to dust and dirt, had high clearance, corrosion and noise during movement. The new solution should avoid this, be light and have a good price-performance ratio.

- Industry: medical equipment

- Success for the customer: iglidur W300 enables bearings with particularly long service life, low coefficients of friction and extremely high abrasion resistance. iglidur Q plain bearings on the other hand are particularly suitable for high loads. At the same time, the prosthesis has become lighter and smoother. The user now has to visit the orthopaedic mechanic much less often.

Problem

Otto Bock Health Care GmbH, a leading global provider of orthopaedic technology, has been offering high-quality and technologically advanced products and services for people with limited mobility for almost 90 years. A new solution had to be found for the various bearing points for one of the specialist's products - the "3R60 EBS" knee joint prosthesis (EBS: Ergonomic Balanced Stride) . Until now, the manufacturer relied on needle and bronze bearings, which, proved to be susceptible to dust, increasing clearance and developed disturbing noises, as well as fretting corrosion during small pivoting movements. The latter can even endanger the prosthesis wearer by blocking the axes. Therefore, an improved design needed to be found that does not require metal. For the new solution, there are also other requirements, such as absolute freedom from maintenance and clearance as well as low wear. They also needed to operate quietly, absorb shocks and offer a good price-performance ratio.Solution

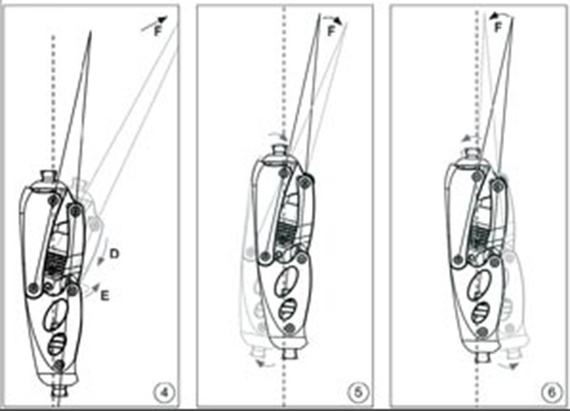

At all bearing points of the artificial knee joint, there are now the plain bearings of the type iglidur W300 and iglidur Q, which replace the previous needle and bronze plain bearings.All representatives of the iglidur W300 family ensure particularly long service life, low coefficients of friction and extremely high abrasion resistance. They are also suitable for soft shafts and resist chemicals. iglidur W300 shows a very high compressive strength despite high elasticity.

The iglidur Q plain bearings on the other hand are particularly recommended for very high loads, under which they have by far the best wear resistance among the iglidur materials. From a radial load of 25MPa, they even surpass plain bearings made of the highly abrasion-resistant iglidur W300. Specific solid lubricants, precisely integrated into the material, ensure that the maintenance-free dry operation is guaranteed under any load. Under the maximum permissible load of 100mPa, the elastic deformation at room temperature is less than 3 percent.

By using the plain plastic bearings, the service life of the prostheses could be increased and the clearance and noise minimised. At the same time, the prosthesis has become lighter and smoother. The user now has to visit the orthopaedic mechanic much less often.