Solving weight and corrosion problems

Lightweight, corrosion-resistant and maintenance-free iglidur plain bearings operate in this aircraft.

In addition to a drylin linear system, numerous iglidur plain bearings are also fitted in this aircraft. No wonder, because the low weight of plastic bearings is a decisive advantage over conventional metal bearings, especially in aviation. In this aircraft, the bearings are housed in the rudder and rotors, where they ensure that the aircraft can be easily navigated at all times.Profile

- What was needed: iglidur plain bearings, drylin linear technology

- Requirements: The bearings were expected to be lightweight and corrosion-resistant.

- Industry: aerospace, aviation industry

- Success for the customer: Overall, the replacement with lighter elements that work lubrication and maintenance-free and are not affected by corrosion makes the solution cheaper and reduces utilisation costs.

Problem

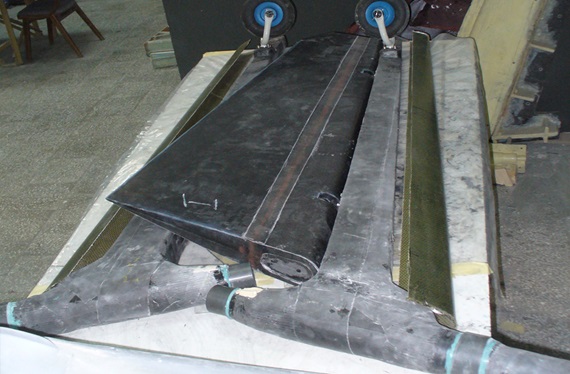

An extremely big problem with flying objects and in aerospace in general is weight and corrosion. This machine therefore needed products for the bearing assemblies that could fulfil both requirements. A suitable answer was sought for several areas of the aircraft, namely the rear suspension struts of the undercarriage, the ball and socket joints of the rudder bearings and in the control rotor. Previously, self-aligning bearings made of heavy steel were used here, which were corrosive and also required frequent maintenance and lubrication. For this reason, lighter elements were sought that work as lubrication-free as possible and are not affected by corrosion.Solution

For the bearing products in the aircraft, those responsible opted for iglidur plain bearings. Specifically, plain bearings of the GFM-6065-50 and GSM-9095-100 models are used in the rear suspension struts on the undercarriage. The GE8FO / GEG8ES plain bearings are used in the ball and socket joints of the rudder bearings. The decision was made to use drylin linear guides in the control rotor. Specifically, the WS 16 single rail is used here together with WJ 200 UM-01-16 bearing housings.In control processes, the use of plastic hinges and guides with plain bearings is a breakthrough and innovation. The use of iglidur polymer bearings in torsion springs in carbon fibre shins is also a kind of innovation and a solution that requires no maintenance during use and lubrication.

Overall, the replacement with lighter elements that work lubrication and maintenance-free and are not affected by corrosion makes the solution cheaper and reduces utilisation costs.