No system downtime: 3D energy supply system for robots in the production of body shells

The triflex RS energy chain systems save costs of over €100,000 per year for MA Automotive.

Tough operating conditions, limited space - and all this at high acceleration forces and cycle rates that impact the energy supply system. In the past, this led to costly downtime of the handling robots, which amounted to a six-figure sum each year. It is not surprising, therefore, that MA Automotive Deutschland GmbH converted to low-profile triflex RS energy chain systems that can be moved in three dimensions. Since then, plant availability has significantly increased.Profile

- What was needed:

e-chain package for retraction system

- Requirements: the energy supply system had to have a very high tensile strength and a low dead weight, with a high acceleration from 0 to 2 m/s it has to withstand very high forces, in addition to the most adverse environmental conditions, such as, amongst other things, accumulating welding dust.

- Industry: automotive industry, body construction

- Success for the customer: there is no more system downtime due to broken cable harnesses, all robots operate trouble-free, the investment has already paid for itself within a very short time.

Problem

Three press lines and eight body-in-white lines as well as around one hundred robots are in use at MA Automotive Deutschland, the highly complex machine park. The company is part of the CLN Holding (MA Automotive, among others), Italy's largest steel service centre based in Turin. The Group has 34 sites in Europe and two production facilities overseas.At the site in Vogtland, the focus is on the production of individual, structural and outer skin parts made of steel and aluminium.

Fully automated robotic systems dominate the body shop. In one area, a robot is responsible for handling boot lids. Here, unpredictable downtime had occurred time and again in the past, as the dress pack assembled on the robot by the factory did not withstand the cramped conditions on site. It got caught, got stuck and kept tearing off. On average, the entire system was down for 657 minutes per year. This meant costs of more than €100,000 a year.

The robot services eight different stations in the system. It picks up individual parts very precisely in the devices, guides them towards other devices before stacking the boot lids in two container towers. The space conditions on site are so tight that there are collision values of a maximum of 3 cm in the plant.

The central requirements for the energy supply system are accordingly high. The energy chain system has to feature very high tensile strength and very low weight. At a fast acceleration of 0 to 2 m/s, it also has to withstand very high forces. Added to this are the most adverse environmental conditions such as welding dust, amongst other things.

Solution

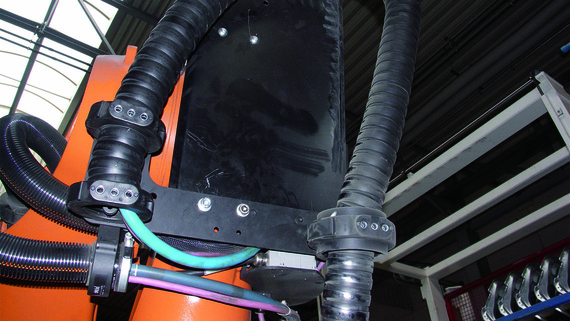

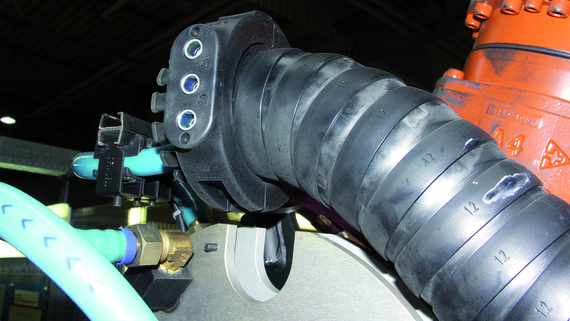

Energy supply systems of the triflex RS system have been in use since 2008, a compact universal module with which the energy chain is guided parallel and close to the robot arm in a space-saving manner. It can be installed on the robot easily and quickly. Thanks to its very low installation height and slender chain guidance, all robot movements can be performed reliably even in the tightest installation spaces. The grease-free chain system has an integrated fibre-rod which keeps the energy chain under tension at all times. In this way, the chain is always guided very close to the robot head, even during complex three-dimensional movements, and no loops or cable stresses are generated.The used triflex TRC70 ensures high flexibility for complicated movements. The high tensile force absorption of the chains is achieved by the so-called "trailer principle" (similar to the "ball/ball socket" mechanism). After locking, ball and socket constitutes an extremely moveable connection that combines smooth movements with optimal traction, ensuring high tensile strength. Finally, the universal mobility of the entire system also enables fast teaching.

Another point is the very good mechanical specifications of the chain. Shock-resistant, abrasion-resistant, tough and dirt-repellent it withstands the welding dust in rough industry use. Setup times are minimised due to the simple connection and suitable accessories, such as strain relief systems and clamps in this case.

A total of four problem robots were retrofitted with triflex R sets. The earlier plant shutdowns have long been a thing of the past. All robots operate trouble-free and within a very short time the investment had already paid for itself.

Steffen Modes, Head of Maintenance, Body Shell Construction at MA Automotive Deutschland

Successfully retrofitted from A to Z

The first energy supply system was installed by igus itself, for which a maximum time window of eight hours was available. After that, the robot had to operate again. Everything worked so smoothly that the customer did the retrofitting of the other three robots himself.The business ratios quickly gave the customer a clear recommendation in favour of the retrofit. With an annual downtime of around eleven hours - equivalent to the cost of more than one shift - the management was quickly convinced. During a meeting on site, the igus salesperson in charge of energy chain systems was then shown the system. Subsequently, they looked together for the best technical and economic implementation. The past few months show that this has been found: from the first day since installation, the multi-dimensionally moving energy supply system with the universal module has proven its worth.