3D printing: the definitive technology trend

Energy chains from igus® ensure the reliable, computer-controlled production of plastic parts

The market research company Gartner ranks 3D printing as one of the TOP 3 technology trends for 2015. It allows companies to develop new products faster, more efficiently and at lower costs. The new series-production printer by Kühling&Kühling is arriving at the perfect time and has already proven itself in various applications worldwide. Special products from igus® play a very important role in this development. The energy chains used are easy to fill, can be incorporated in a compact way and can handle the high accelerations in the system.

The driving force behind the positive market trend in 3D printing is the fact that industrial companies are recognising its potential more and more. They are upgrading and buying systems for prototyping and other areas of application - and the trend is on the rise. The market research company Gartner explains that companies use 3D printing technology with the goal of achieving increased agility compared to the competition, lowering costs as well as creating innovations for future products. One area where computer-controlled components are being used is in medical technology, where it is now no longer necessary to mill complicated structures from solid materials at high costs. They are also being used for commercial medium-sized production batches of several hundred components. They also offer diverse possibilities for model construction in architecture firms.

Cost-effective printers for industrial purposes

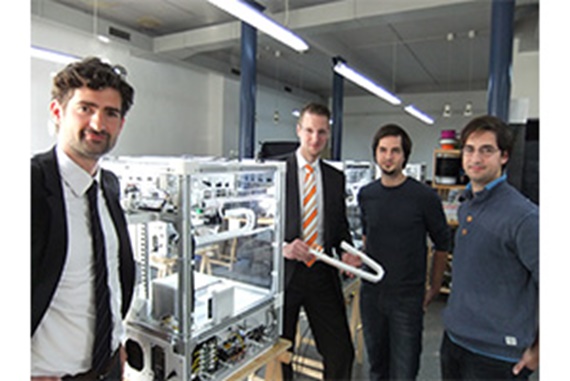

These kinds of systems are being produced by companies such as Kühling&Kühling, based in Kiel, Germany. The company was founded by mechatronics engineers Jonas and Simon Kühling in 2012 and its focus is on the development and production of open-source hardware in the realm of 3D printers. The first series-production product, the RepRap Industrial, is the result. It was unveiled at the end of last year after 1.5 years of development. "The printer is a cost-effective solution for reliable and high-quality rapid prototyping, particularly in the case of highly demanding continuous service," says Jonas Kühling. Ongoing development continues and it just received a significant update and various improvements with its v1.1.0 version. Any materials that fulfil certain basic specifications can be processed. This ranges from high-strength thermoplastics to fibre-filled plastics to rubber-elastic materials.

These kinds of systems are being produced by companies such as Kühling&Kühling, based in Kiel, Germany. The company was founded by mechatronics engineers Jonas and Simon Kühling in 2012 and its focus is on the development and production of open-source hardware in the realm of 3D printers. The first series-production product, the RepRap Industrial, is the result. It was unveiled at the end of last year after 1.5 years of development. "The printer is a cost-effective solution for reliable and high-quality rapid prototyping, particularly in the case of highly demanding continuous service," says Jonas Kühling. Ongoing development continues and it just received a significant update and various improvements with its v1.1.0 version. Any materials that fulfil certain basic specifications can be processed. This ranges from high-strength thermoplastics to fibre-filled plastics to rubber-elastic materials.

Printers for personal or model construction use only allow the utilisation of a limited selection of print materials. By and large, so-called bio-plastic made from corn is being used in these cases. This material generally cannot withstand the technical demands of industrial applications. This type of plastic already fails at temperatures above 45 °C whereas temperature limits in an industrial setting are significantly higher. Compared to other 3D printers with similar performance capability, the RepRap Industrial stands out specifically due to its price. It costs about 25-30% less than comparable systems. Its success proves Kühling&Kühling right: The printers are being sold worldwide, quantities are continuously increasing and have quadrupled within one year.

German purchased parts ensure the quality of the end product

The two company founders place special importance on purchased parts from the same geographical area, "We have compared components from all over the globe. In Germany, we can get the quality we need and ensure long-term delivery capabilities. " The energy chains from Cologne-based igus® GmbH were their choice for the guidance of individual cables. Due to their low installation height and narrow bending radii, they are ideally suited for the narrow installation spaces of 3D printers. They are also light and can handle the rapid accelerations that occur during the printing process without slowing down the print head.

The two company founders place special importance on purchased parts from the same geographical area, "We have compared components from all over the globe. In Germany, we can get the quality we need and ensure long-term delivery capabilities. " The energy chains from Cologne-based igus® GmbH were their choice for the guidance of individual cables. Due to their low installation height and narrow bending radii, they are ideally suited for the narrow installation spaces of 3D printers. They are also light and can handle the rapid accelerations that occur during the printing process without slowing down the print head.

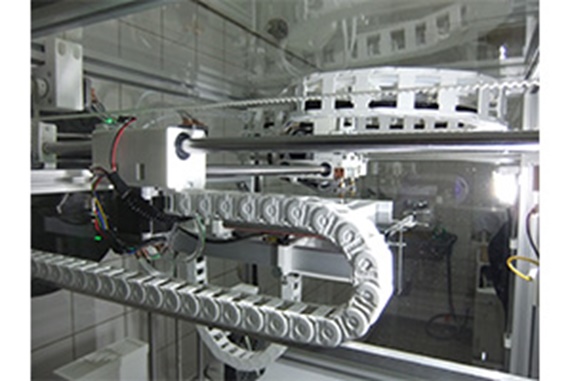

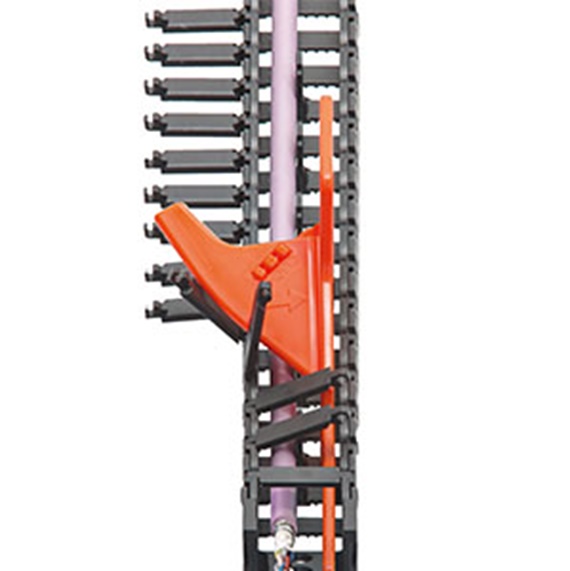

Various igus® energy chains are incorporated into the RepRap Industrial, such as the E2i.15 model from the compact E2 micro product family. It features an exceptional space-saving design and smooth unwinding movements. The very precise guidance of the chain was of particular importance for company owners Jonas and Simon Kühling. "In other machines, simple tubes are being used," says Simon Kühling. "These can however simply tip or bend during the fast movements of the 3D printing process. This can result in machine failure or even cable defects. " The E2i.15 product range has a number of unique features: It can be used universally since a mounting bracket with strain relief potential is optionally available, called Quick Flange, for front mounting. Large, installation-friendly pins ensure high stability. The smooth design lines protect the cables from damage, making the energy chain very cable-friendly.

While a built-in "brake" reduces noise emission, an angular stop system ensures high fill weight and a long unsupported length that provides a significant benefit to the RepRap Industrial. All products in this energy chain system come with a supplied chain opener. It allows you to open one metre of energy chain within two seconds, which is especially helpful for simplifying the installation of cables. igus® offers 1,040 different chainflex® cables specifically designed and developed for use in energy chains. This complete cable product range includes control, motor, servo and measuring system cables as well as data, bus and fibre optic cables for highly diverse application areas and narrow bending radii down to 4xd.

Kühling&Kühling also utilises products from the second large business area of igus®, namely lubrication free plastic slide bearings. Steel shafts and linear guides with liners made from iglidur® high-performance plastics are being used in the 3D printer as well as high helix lead screw units and plastic threaded nuts as axis drives. These do not require external lubrication, have the same design as recirculating ball bearings but are more cost-effective, and are easy to install.

Kühling&Kühling also utilises products from the second large business area of igus®, namely lubrication free plastic slide bearings. Steel shafts and linear guides with liners made from iglidur® high-performance plastics are being used in the 3D printer as well as high helix lead screw units and plastic threaded nuts as axis drives. These do not require external lubrication, have the same design as recirculating ball bearings but are more cost-effective, and are easy to install.

Products for any application

To ensure that any application, even those outside the realm of 3D printing, can be equipped with just the right energy chain, igus offers a comprehensive online catalogue as well as various selection and configuration tools. One of the most important calculation programmes is, for example, the determination of a product's service life. After selecting the energy chain and the application option "unsupported" or "gliding" as well as other base conditions such as fill weight, travel, speed and acceleration, the service life of the energy chain is determined. As an option, it is possible to enter outside influences such as dirt, impact and the ambient temperature. The expected service life is specified in double strokes and kilometres. By clicking on "Catalogue page of the series selected", interested parties will receive further information and can enquire about or order the energy chain in the catalogue. QuickSpec is available for particularly urgent orders.

To ensure that any application, even those outside the realm of 3D printing, can be equipped with just the right energy chain, igus offers a comprehensive online catalogue as well as various selection and configuration tools. One of the most important calculation programmes is, for example, the determination of a product's service life. After selecting the energy chain and the application option "unsupported" or "gliding" as well as other base conditions such as fill weight, travel, speed and acceleration, the service life of the energy chain is determined. As an option, it is possible to enter outside influences such as dirt, impact and the ambient temperature. The expected service life is specified in double strokes and kilometres. By clicking on "Catalogue page of the series selected", interested parties will receive further information and can enquire about or order the energy chain in the catalogue. QuickSpec is available for particularly urgent orders.